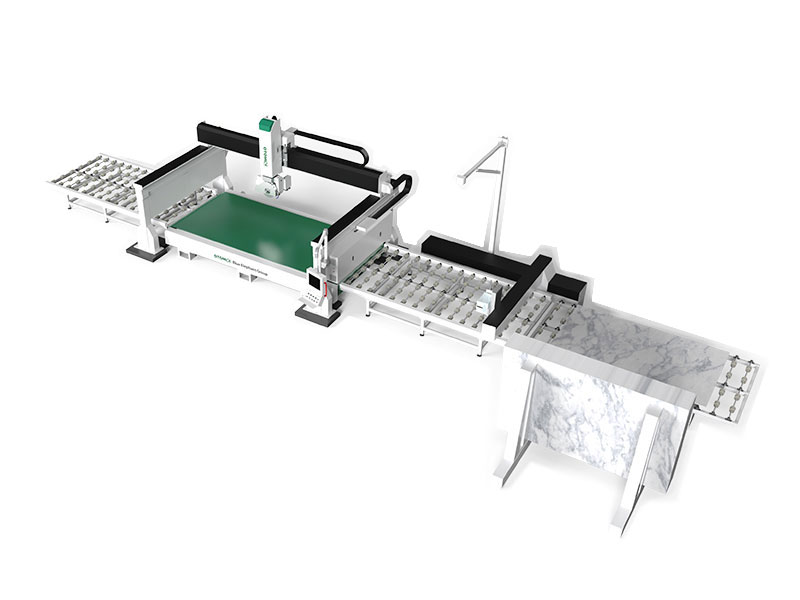

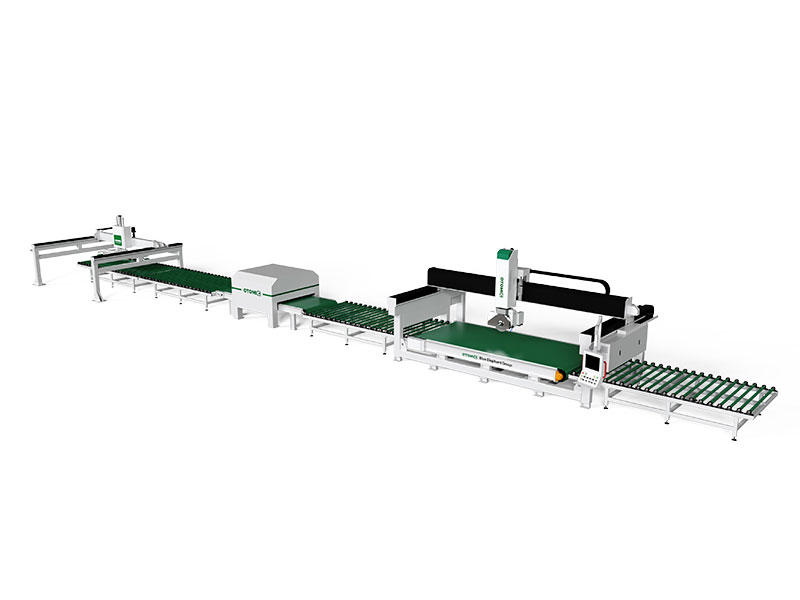

01. Introduction of Upgraded 5-Axis Stone CNC Bridge Saw with Camera

Technological innovations continue shaping the future of various industries, including the stone processing sector. One significant breakthrough comes in the form of an upgraded 5-axis stone CNC bridge saw, boasting built-in camera capabilities. This cutting-edge machine offers unprecedented levels of precision, efficiency, and versatility, elevating stone fabrication to new heights. In this article, we delve deeper into understanding the functionalities and applications of this revolutionary device.

02. Upgraded Features and Capabilities

This next-generation 5-axis stone CNC bridge saw brings numerous enhancements compared to traditional models:

Integrated Camera System – The most prominent feature is undoubtedly the addition of a high-resolution camera. Positioned strategically above the working area, the camera takes real-time images of the raw plates before any processing begins. These visuals appear instantly within the system, allowing operators to pinpoint the exact location of the plate relative to the cutting apparatus. Such alignment accuracy translates to less waste, fewer errors, and overall cost savings.

Slate Cutting and Drilling – Featuring robust saw blades and interchangeable cutter heads, this machine enables seamless execution of tasks such as slate cutting or drilling. Combining the power of 5 axes, intricate profiles, angled grooves, or curved shapes pose no challenge, delivering exceptional outcomes each time.

User-Friendly Software Interface – Modern software platforms accompany this advanced hardware configuration, providing intuitive user experiences for even novice operators. Configurable settings, step-by-step guidance, and remote monitoring capabilities make controlling the machine effortless.

Industry Applications of Upgraded 5-Axis Stone CNC Bridge Saw with Camera

Given its impressive array of features, this upgraded 5-axis stone CNC bridge saw finds relevance in numerous stone processing domains:

Stone Wall Decoration – Creating stunning stone walls requires meticulous detailing and flawless execution. Utilizing the advanced imagery offered by the integrated camera system, artisans can achieve breathtaking murals and reliefs, adding depth and character to interior spaces.

Kitchen and Bathroom Countertops – Given the ever-growing demand for bespoke kitchen and bath surfaces, having access to precise cutting technology proves indispensable. Producing perfectly fitted countertops complete with sink holes, tapered edges, or recessed drainboards becomes feasible with ease.

Other Stone Processing Industries – Beyond aesthetic applications, industrial uses also benefit from this technological leap. Manufacturers engaged in creating components for infrastructure, architecture, sculpture, or engineering enjoy enhanced productivity, consistency, and quality assurance.

Conclusion of Upgraded 5-Axis Stone CNC Bridge Saw with Camera

An upgraded 5-axis stone CNC bridge saw equipped with a camera presents a compelling proposition for stakeholders involved in the stone processing value chain. From streamlined workflows to improved end products, embracing such innovative technologies fosters growth, promotes sustainability, and sets new standards for excellence. Leveraging these advances equips professionals with the necessary tools to excel in an increasingly competitive marketplace, driving long-term success and customer satisfaction alike.