In the world of CNC machinery, sourcing the right CNC bridge saw machine manufacturer can be the key to ensuring your business’s success. This article will guide you through the two primary methods of connecting with manufacturers and provide you with the essential tips for identifying quality CNC bridge saw manufacturers online. Additionally, we will introduce you to the top 10 CNC bridge saw brands worldwide, explain the main features and functions of CNC bridge saw machines, and explore innovative ways to use the internet to discover the best suppliers.

And Recently, The 134th Canton Fair is in progress now, it started from October 15th, 2023,

The onsite exhibition:

Phase 1: October 15th to 19th

Phase 2: October 23rd to 27th

Phase 3: October 31st to November 4th

Additionally, the online exhibition, available through the online platform, will be extended for approximately six months, starting from September 16th, 2023, and continuing until March 15th, 2024. Hope buyers and suppliers get harvest in the famous fair.

Part 1: The Two Paths to Finding the Right CNC Bridge Saw Manufacturer

Sourcing the ideal CNC bridge saw machine manufacturer requires a strategic approach that aligns with your specific business needs. One of the primary considerations is the choice between online sourcing and trade fair networking. In today’s digital age, many clients prefer the convenience of the internet for preliminary research and information gathering. The vast wealth of data available online simplifies the initial screening process and allows potential buyers to explore various manufacturers without geographical limitations. On the other hand, trade fairs offer a unique and invaluable opportunity for hands-on interaction with machines and professionals. These in-person experiences can help build trust and establish lasting partnerships.

Part 2: Sourcing Quality CNC Bridge Saw Manufacturers Online

If you choose to embark on your CNC bridge saw manufacturer search online, a comprehensive evaluation is crucial. There are multiple factors to consider when assessing potential manufacturers to ensure quality and reliability.

Firstly, examine their website to gauge their professionalism and commitment to transparency. A manufacturer’s website should provide a clear overview of their products, capabilities, and services. It’s also a valuable source of information for understanding the manufacturer’s core values and commitment to quality.

Additionally, delve into the manufacturer’s background. Look for indicators of their expertise, such as the number of years they’ve spent in the industry. Experience often correlates with an understanding of customer needs and a commitment to product excellence.

Another critical aspect to investigate is the size of the manufacturer’s workshop and the number of employees they have. A well-equipped, spacious workshop typically signifies a commitment to production quality and capacity. Smaller workshops can be highly specialized and nimble, offering unique benefits as well.

To ensure that the manufacturer is capable of handling the scale of your project, check their export records. The volume and variety of exports can provide insights into the manufacturer’s reach and efficiency.

Don’t forget to inquire about their after-sales service and support. This is an essential aspect of your partnership with the manufacturer. Timely maintenance and repair services can minimize downtime and keep your production running smoothly.

In your search, don’t overlook customer reviews and testimonials. These can offer a glimpse into the experiences of others who have worked with the manufacturer.

Part 3: The World’s Top 10 CNC Bridge Saw Brands: A Cut Above the Rest

When it comes to CNC bridge saw machines, precision, quality, and innovation are the cornerstones of success. As businesses seek reliable solutions for cutting, carving, and shaping stone, quartz, granite, and marble, these top 10 CNC bridge saw brands stand out in the global market. Let’s explore each brand and their distinct offerings, which have earned them a spot on this esteemed list.

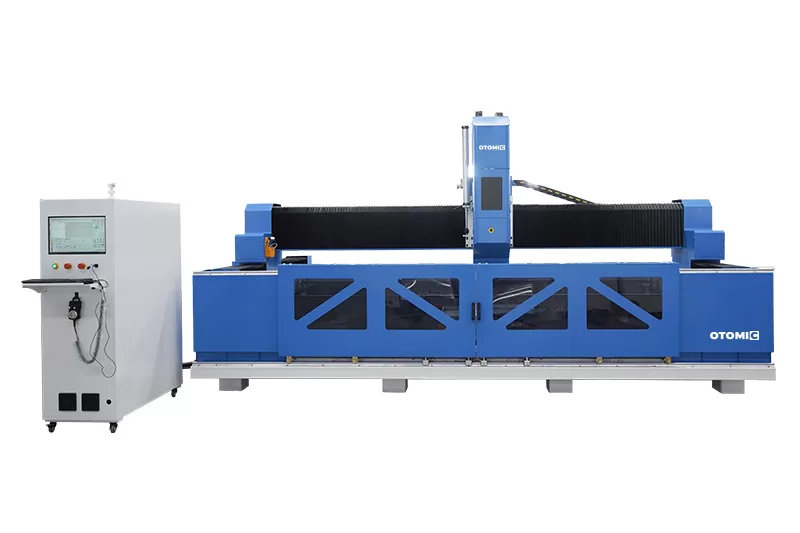

1. Otomic

Otomic is a name synonymous with cutting-edge technology. Renowned for their 4-axis and 5-axis CNC bridge saw machines, Otomic has set industry standards with their precision and efficiency. Their innovative solutions make them a go-to choice for clients seeking top-tier bridge saw machines worldwide.

2. Breton

Breton’s legacy is deeply rooted in its extensive experience spanning decades. The company prides itself on offering comprehensive solutions for stone fabrication and processing. Their CNC bridge saw machines are celebrated for their high quality and sophisticated design, earning Breton an esteemed reputation.

3. GMM

GMM stands out with a wide range of CNC bridge saw machines, catering to various needs within the stone industry. Their commitment to providing cutting-edge technologies and versatile solutions ensures that clients find the perfect bridge saw machine for their projects.

4. THIBAUT

Known for their French craftsmanship, THIBAUT specializes in precision CNC bridge saw machines. Their focus on research and development ensures that their products are at the forefront of the industry, delivering remarkable results for businesses worldwide.

5. Bideseimpianti

Bideseimpianti is a leading name in the CNC bridge saw sector. Their dedication to quality, technological innovation, and tailor-made solutions makes them a trusted partner for businesses seeking precision stone cutting machines.

6. Prussiani Engineering

Prussiani Engineering’s CNC bridge saw machines are synonymous with efficiency and accuracy. These Italian-engineered machines are designed to meet the most demanding requirements of the stone industry, making them a top choice for discerning customers.

7. MarmoMachines

MarmoMachines has a rich history of providing quality stone machinery. Their range of CNC bridge saw machines combines functionality with cutting-edge technology, offering high-performance solutions for a broad spectrum of stone fabrication needs.

8. Northwood Machine

Northwood Machine is an American brand known for its robust CNC bridge saw machines. With a focus on durability and reliability, their machines are an excellent choice for businesses seeking long-lasting, high-quality solutions.

9. Park Industries

Park Industries is a trusted name in the stone fabrication sector. Their CNC bridge saw machines offer a blend of precision, efficiency, and user-friendliness. Park Industries’ commitment to quality has secured them a spot among the industry’s best.

10. Montresor

Montresor’s CNC bridge saw machines are revered for their precision and performance. This Italian brand’s solutions cater to a wide range of stone processing needs, making them a top choice for businesses worldwide.

In conclusion, these top 10 CNC bridge saw brands exemplify excellence in stone fabrication technology. Each brand brings a unique blend of innovation, precision, and quality to the global market. Choosing the right CNC bridge saw machine from among these renowned brands can empower businesses in the stone industry to reach new heights of productivity and craftsmanship.

Part 4: Unveiling the Craftsmanship: Features and Functions of CNC Bridge Saw Machines

CNC bridge saw machines are the unsung heroes of the stone fabrication industry. These remarkable pieces of equipment are instrumental in transforming raw stone slabs into exquisite countertops, statues, and architectural marvels. Let’s delve into the world of CNC bridge saw machines and explore their unique features and functions that make them indispensable to the stone processing sector.

Video of CNC Bridge Saw Machine for Stone Slab Cutting

Precise Cutting with Unmatched Accuracy:

One of the hallmark features of CNC bridge saw machines is their unparalleled precision. These machines are equipped with advanced cutting heads that can make intricate cuts with the utmost accuracy. Whether it’s crafting a complex design or achieving clean, straight cuts, CNC bridge saws can do it all. With computer-guided precision, the margin for error is drastically reduced, ensuring that each piece cut is identical and perfectly shaped.

3D Stone Carving and Sculpting:

Beyond mere cutting, CNC bridge saw machines have the remarkable ability to sculpt stone in three dimensions. Artists and stonecrafters can create intricate reliefs, sculptures, and detailed carvings with ease. This 3D carving capability opens up a world of creative possibilities, allowing for the production of captivating and artistic stone pieces that add a touch of elegance to any project.

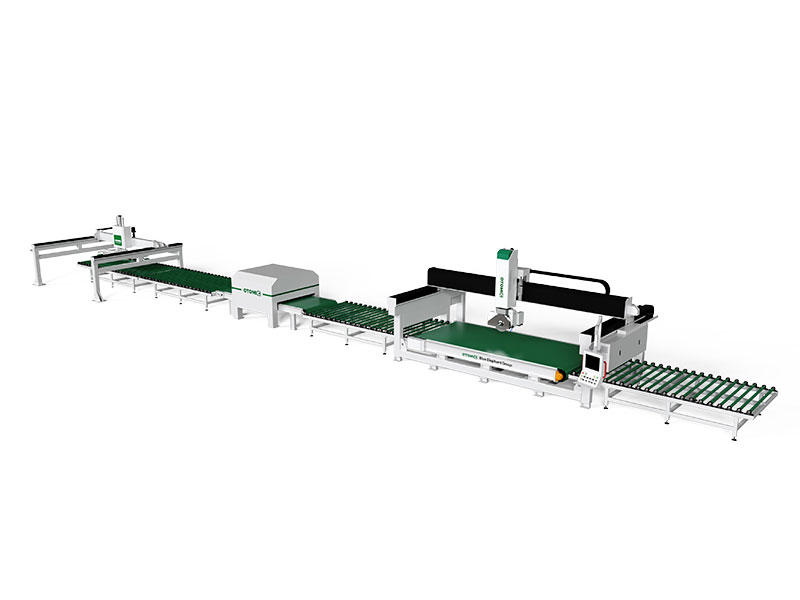

Efficient and Fast Production:

CNC bridge saw machines are designed to optimize production efficiency. With automatic tool changers and computer numerical control, these machines work tirelessly to meet production demands. In large-scale stone processing facilities, CNC bridge saws ensure that orders are fulfilled with speed and precision, making them invaluable for meeting tight deadlines and handling high production volumes.

Edge Profiling and Polishing:

Creating a polished edge on stone slabs is an art form, and CNC bridge saw machines are masters of this craft. These machines can be programmed to profile and polish the edges of stone pieces, leaving a professional and glossy finish. The versatility of these machines extends to the many different edge profiles available, allowing customization to suit various project requirements.

Hole Boring and Sinking Sinks:

CNC bridge saw machines are not limited to straight-line cutting. They can bore holes and cut openings in stone slabs with precision. This capability is invaluable when crafting sinks, ensuring that they fit seamlessly into countertops. The ability to sink sinks and bore holes with precision is a time-saving and quality-enhancing feature of these machines.

Versatile Material Handling:

CNC bridge saw machines are adaptable to various materials, from natural stone like granite and marble to engineered quartz and even glass. This versatility makes them a valuable addition to fabrication shops that handle a wide range of materials, providing endless possibilities for creative projects.

Conclusion:

CNC bridge saw machines are the backbone of the stone fabrication industry. Their array of features and functions, from precise cutting to 3D carving and edge profiling, are essential tools for crafting exquisite stone pieces. The efficiency, versatility, and creative potential offered by these machines have made them a cornerstone of modern stonemasonry and design. With CNC bridge saw machines, artisans and fabricators can bring the beauty of stone to life in new and captivating ways.

Part 5: How to Leverage the Internet to Find Reliable Suppliers

In the ever-evolving landscape of global trade, the internet has emerged as an indispensable tool for finding suppliers. The digital age has ushered in a new era of connectivity and accessibility, making it easier than ever to identify and collaborate with suppliers across the globe. Whether you’re sourcing machinery, raw materials, or any other products, the internet provides a vast marketplace for both buyers and suppliers. In this article, we’ll explore how to effectively harness the power of the internet to find reliable suppliers and establish successful partnerships.

1. Comprehensive Online Directories:

The internet is teeming with online directories and marketplaces that connect buyers with suppliers. Industry-specific platforms like Alibaba, ThomasNet, and Global Sources are treasure troves of supplier information. These directories allow you to browse through profiles, product catalogs, and user reviews, providing valuable insights into a supplier’s reputation and capabilities.

2. Social Media and Networking:

Social media platforms like LinkedIn, Facebook, and Twitter have evolved into more than just places for personal connections. They now serve as hubs for professional networking and can be goldmines for finding suppliers. Join industry-specific groups and forums where suppliers often share their expertise and showcase their products. Engaging with these communities can lead to valuable supplier contacts.

3. B2B Marketplaces:

Business-to-business (B2B) marketplaces offer a streamlined process for identifying and evaluating suppliers. Websites like Global Trade, EC21, and TradeIndia connect buyers with suppliers from around the world. They offer features such as supplier verification, secure payment systems, and negotiation tools that simplify the procurement process.

4. Supplier Websites:

Many suppliers maintain their websites, providing comprehensive information about their products, services, and company background. A well-maintained website is a sign of professionalism and a commitment to transparency. These sites often include contact information, product catalogs, and details about manufacturing capabilities.

5. Sourcing Agents and Online Services:

For those who prefer personalized assistance, sourcing agents or online services can be invaluable. Sourcing agents work as intermediaries between buyers and suppliers, leveraging their industry knowledge and connections to find the right suppliers for your needs. Online services, like Sourcify or Sourcengine, offer platforms to connect with experienced sourcing professionals.

6. Online Trade Shows and Webinars:

While traditional trade shows still have their place, many events have moved online. Participating in virtual trade shows and webinars can provide a wealth of information and contacts. These events offer opportunities to interact directly with suppliers, ask questions, and explore their offerings.

7. Background Checks and Due Diligence:

In the digital age, due diligence is paramount. Research potential suppliers thoroughly. Investigate their history, reviews, and reputation. Online databases, company registers, and government websites can provide insights into a supplier’s legal and financial standing.

8. Communication and Verification:

Once you’ve identified potential suppliers, open lines of communication. Use video calls, email, or instant messaging to discuss your requirements. Verify certifications, licenses, and quality control processes. Transparency and clear communication are key to building a trustworthy supplier relationship.

The internet has revolutionized supplier sourcing, offering a multitude of avenues to discover reliable partners. However, it’s essential to approach the process with discernment and diligence. By leveraging online resources and applying a thoughtful, research-driven approach, you can confidently navigate the digital era and find suppliers that meet your specific needs.