Features

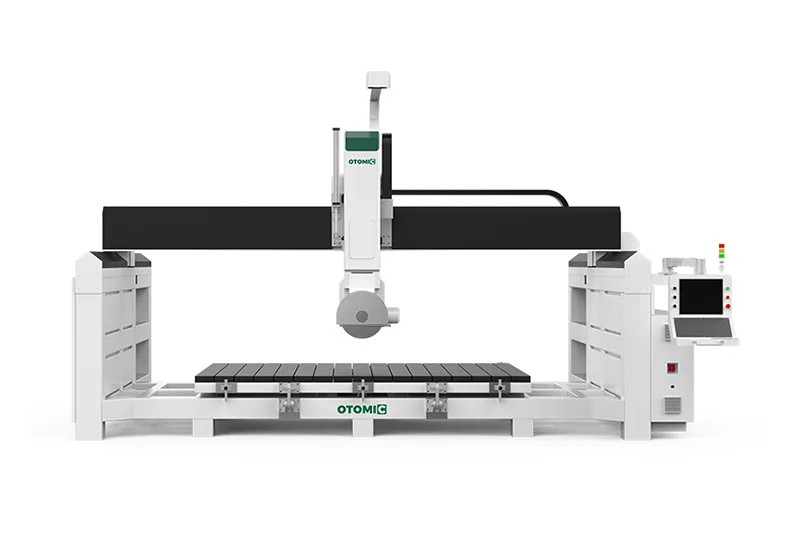

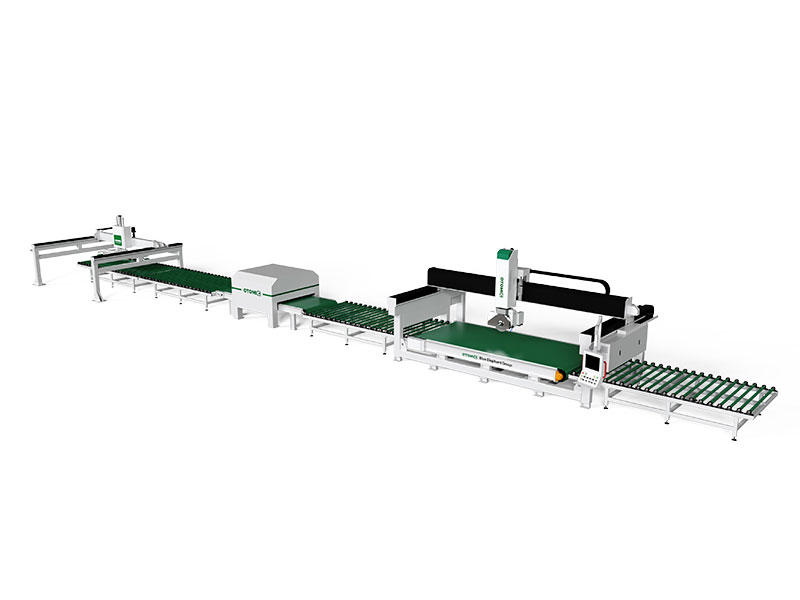

- CNC Bridge Saw cutting machine is a really cool tool in stone fabrication industry with precision and efficiency.

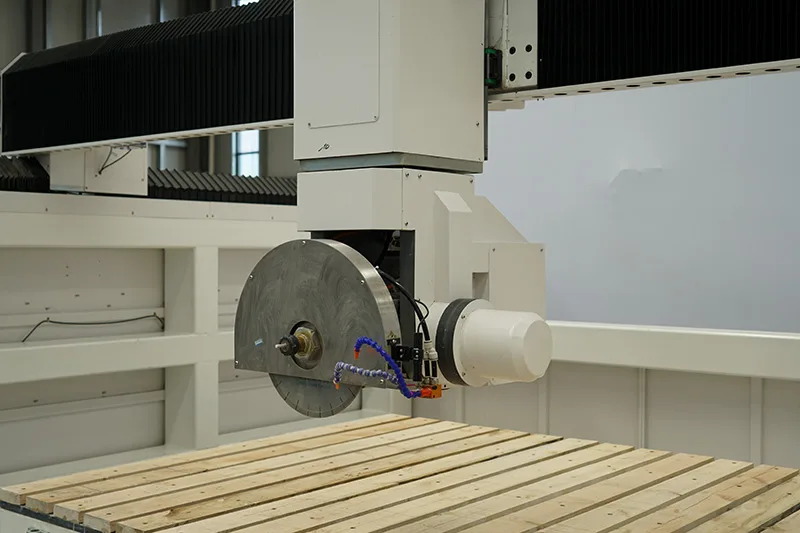

- Multi-Axis Cutting Capability: One of the primary benefits of a CNC bridge saw or automatic bridge saw is its multi-axis cutting capability, which enables it to make cuts in multiple directions, including miter, bevel, and compound angles. This makes it perfect for cutting complex shapes and designs in a wide array of materials like stone, glass, metal, and plastic.

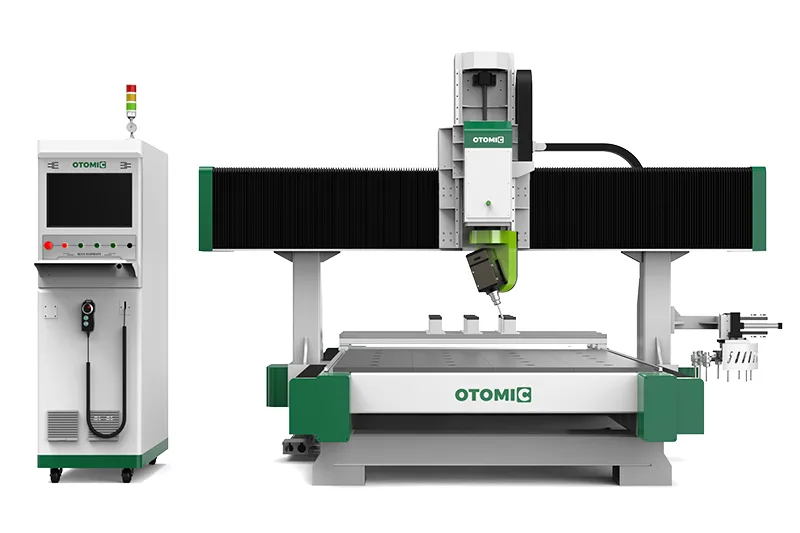

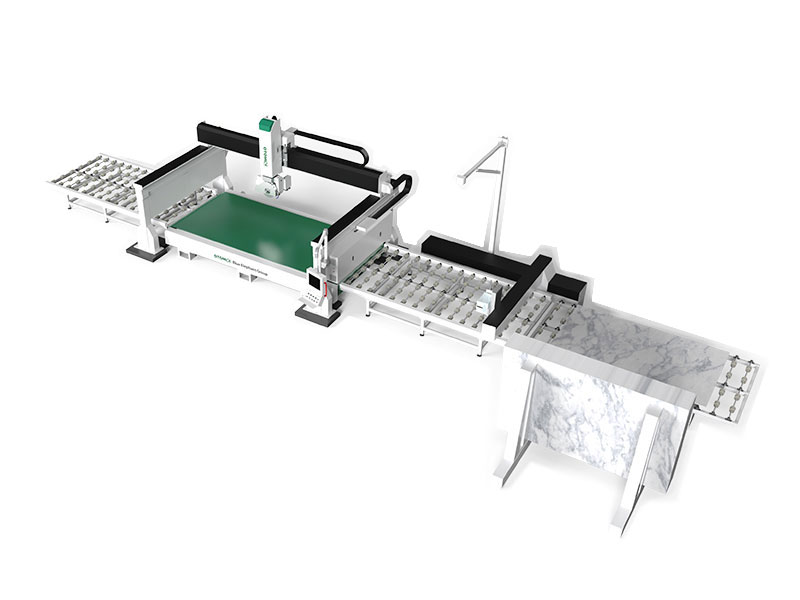

- Automated Operation: Designed for maximum efficiency and accuracy, CNC bridge saws and automatic bridge saws offer automated operation, complete with automated material loading and unloading systems, tool changing capabilities, and programmable controls. This allows for quick and straightforward setup and operation.

- High Precision and Accuracy: Featuring advanced motion control systems and high-resolution encoders, CNC bridge saws and automatic bridge saws provide exceptional precision and consistency, ensuring tight tolerances and reliable repeatability.

- Powerful Spindles and Cutting Tools: For demanding cutting applications, these machines boast robust spindle power (up to 60 HP) and a selection of long-lasting cutting tools, such as diamond blades, abrasive water jets, and milling cutters.

- User-Friendly Design and Enhanced Safety: Built with ergonomics and safety in mind, CNC bridge saws and automatic bridge saws commonly have adjustable workstations, intuitive interfaces, and built-in safety mechanisms. Additional optional features might encompass dust collection systems, coolant tanks, and soundproofing solutions.

- Versatile Programming Choices: Offering flexible programming alternatives, users can opt between manual data entry, DXF file imports, or CAM software compatibility based on their particular demands and inclinations.

Parameters

| 4 axis 5 axis CNC stone bridge cutting machine | ||

| Working travel | X, Y, and Z | to your projects |

| C axis | ±360° | |

| A axis | 4 axis:0,45°;5 axis:0-90°; | |

| Speed | X Y axis | 30m/min |

| Servo motor | X Y Z A C | absolute servo motor |

| Guide rail | X, Y, and Z: # 30 | |

| Rack | X、Y | 2MT-WIN |

| Worktable | Structure | Square timber |

| Worktable size | Customizable to your projects | |

| Turning angle | 0-80° | |

| Max. weight for turning | 800KG | |

| Saw blade | Dimension | 450mm |

| Max. cutting thickness | 100mm | |

| Ball screw | Z | 3210PREYP |

| Reducer | X/Y: Japan SHIMPO | |

| Saw motor | 11KW motor, rated: 3000r/min | |

| Inverter | 15KW BRICH | |

| Working air pressure | 0.7-0.8Mpa | |

| Voltage | To your needs | |

Reviews

There are no reviews yet.