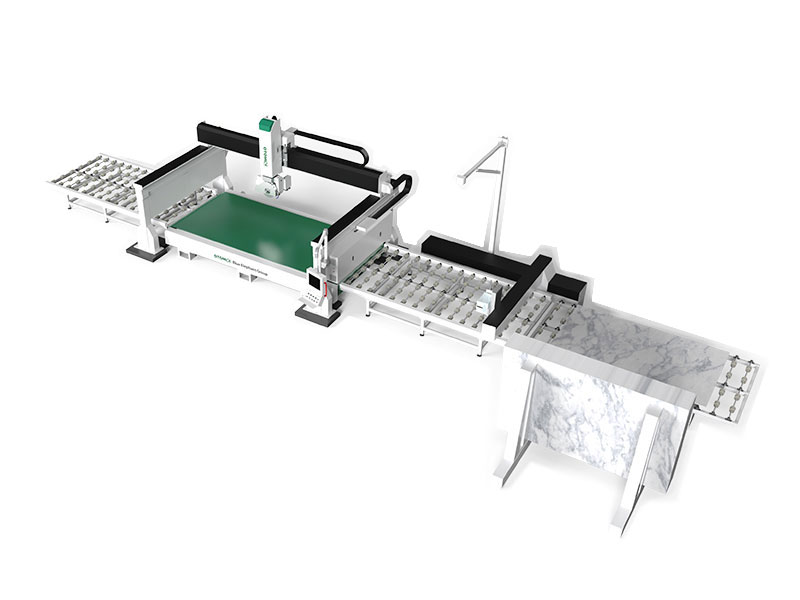

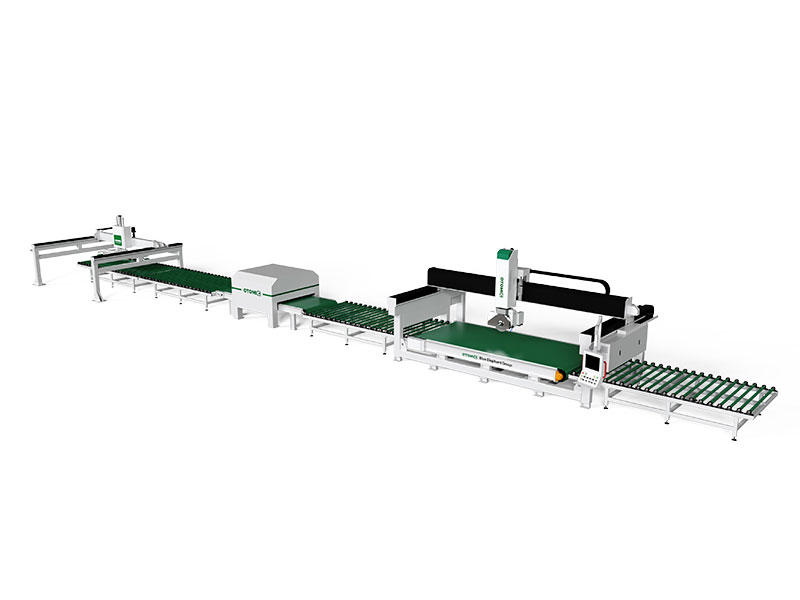

01. Five-Axis CNC Bridge Saws Introduction

Stone fabrication is a growing industry driven by demand for natural stones used in residential and commercial projects worldwide. The integration of advanced technology into traditional methods has revolutionized production capabilities, leading to higher efficiencies, improved accuracy, and increased product diversity. Among these technologies, five-axis Computer Numerical Control (CNC) bridge saws have emerged as powerful tools transforming the landscape of modern stone fabrication shops. In this article, we explore the untapped potential of stone fabrications using five-axis CNC bridge saws.

02. The Evolution of Stone Fabrication Technology

Traditionally, stone fabrication relied heavily upon manual techniques requiring skilled laborers operating handheld equipment. However, advancements in computerization led to the development of CNC machinery designed specifically for the stone industry. Initially limited to three axes, these early models provided basic functionality such as straight line cutting. As technology progressed, so did expectations for greater speed, precision, and adaptability. Enter the era of multi-axis CNC systems – notably, the five-axis CNC bridge saw.

03. Benefits of Five-Axis CNC Bridge Saws

Five-axis CNC bridge saws represent the pinnacle of innovation in stone fabrication due primarily to their enhanced degree of freedom compared to conventional three-axis alternatives. By incorporating two additional rotational axes, these sophisticated devices allow manufacturers to perform complex cuts quickly and precisely, opening up new possibilities within the realm of stonework creation. Here are some notable benefits:

Increased Design Flexibility – Five-axis CNC bridge saws enable fabricators to create intricate patterns, curves, and angles previously unachievable via standard methods. This capability allows designers more creative liberty when crafting unique pieces tailored to specific client needs.

Efficiency Boost – Multi-axis motion facilitates simultaneous processing along several planes, significantly shortening lead times without compromising quality. Moreover, automated features such as tool changes minimize operator intervention, further optimizing production cycles.

Improved Surface Finishes – Advanced software algorithms integrated within five-axis CNC bridge saws calculate optimal cut paths to ensure consistently clean edges, thereby eliminating post-processing steps typically required following three-axis operations.

Safety Enhancement – Automated operation reduces human interaction with potentially hazardous machinery, decreasing risks associated with manual manipulation and ultimately promoting safer workspaces.

04. Applications of Five-Axis CNC Bridge Saws Across Industry Segments

From countertops to monumental structures, five-axis CNC bridge saws cater to a wide range of applications across diverse sectors. Some examples include:

Residential Kitchen Countertops – Custom kitchen islands featuring elegant curves or waterfall designs can now be realized effortlessly thanks to five-axis CNC technology.

Commercial Projects – Hotels, offices, and retail spaces often incorporate elaborate marble cladding, mosaics

Conclusion of Five-Axis CNC Bridge Saws in Stone Fabrication Industry

In summary, five-axis CNC bridge saws hold immense potential for unlocking new possibilities in the stone fabrication industry. Through heightened design flexibility, improved surface finishes, increased safety, and reduced turnaround times, these innovative machines empower fabricators to push boundaries and redefine limits. Furthermore, they open doors to novel opportunities spanning myriad segments, ranging from residential installations to grandiose commercial ventures.

As technology continues advancing, it becomes increasingly evident that adopting state-of-the-art solutions propel businesses forward in terms of competitiveness, sustainability, and growth. Embracing five-axis CNC bridge saws represents just one facet of this ongoing digital transformation sweeping through the sector. Ultimately, those who remain vigilant and nimble amidst change stand poised to capitalize on emerging trends, setting themselves apart as leaders within the dynamic world of contemporary stone fabrication.