Features

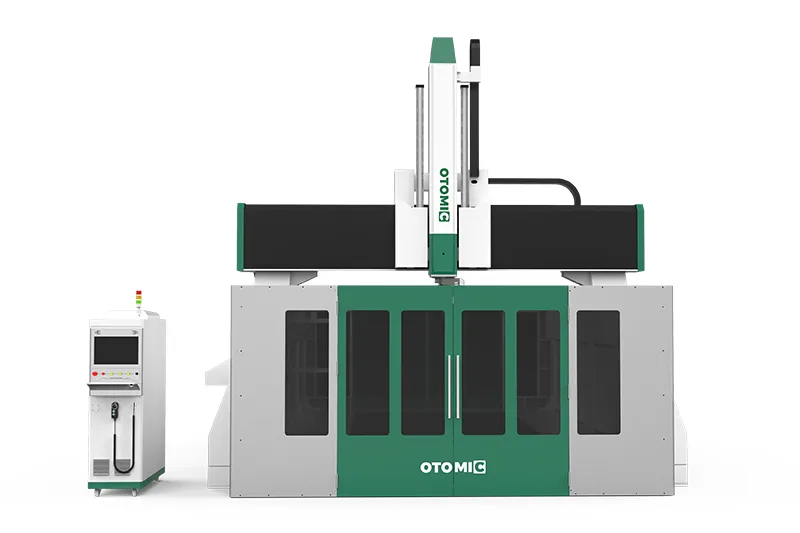

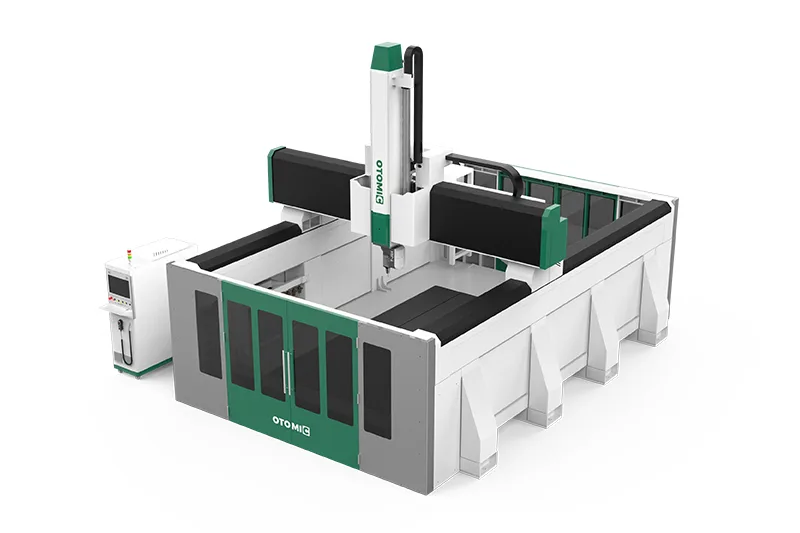

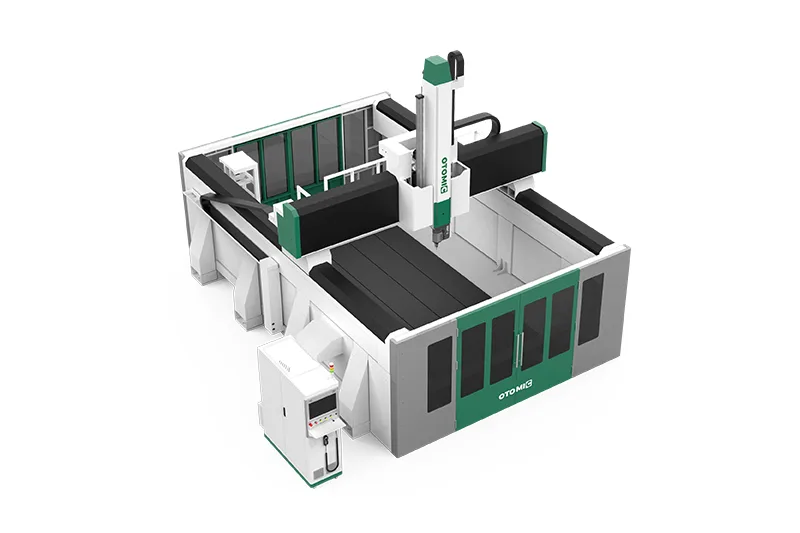

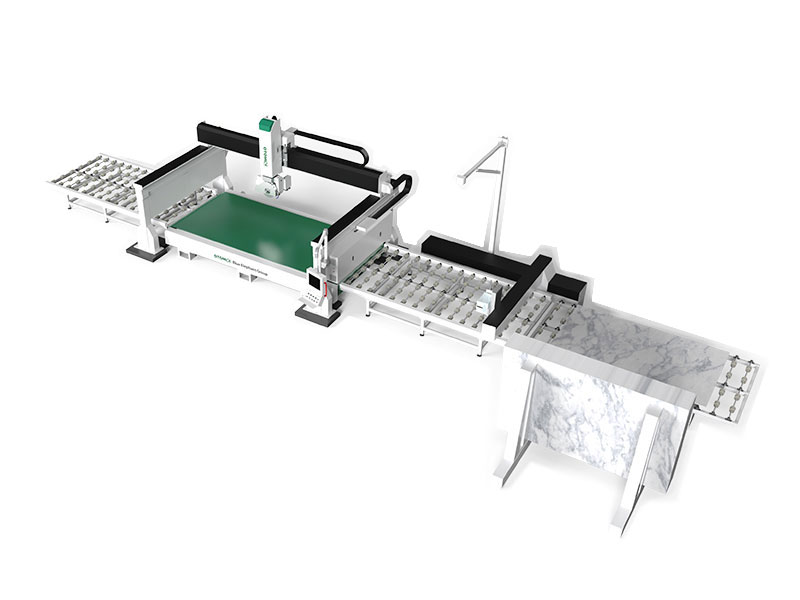

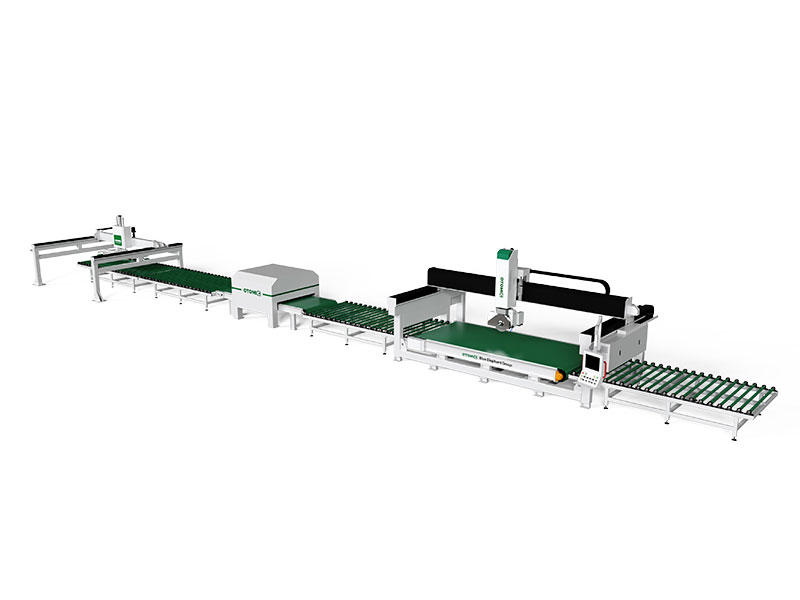

- Heavy-duty construction: The CNC machine is designed with a robust and durable structure to handle the demands of carving wood and foam materials effectively.

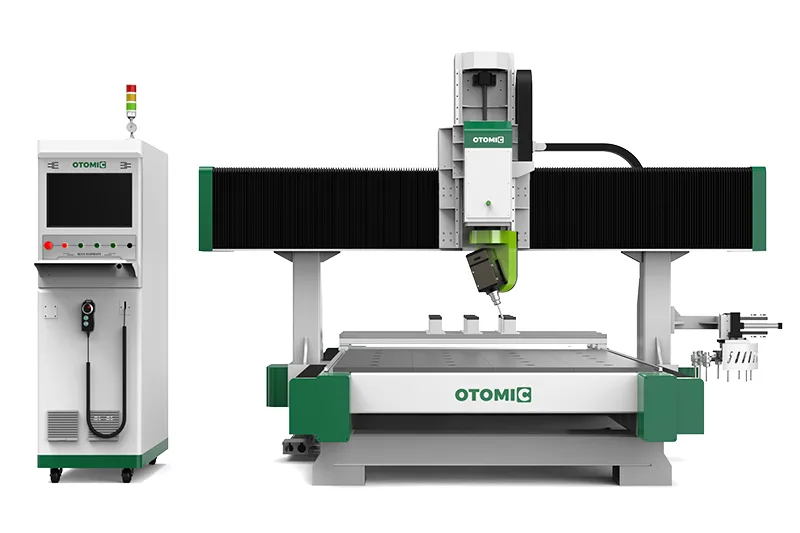

- 5-axis capability: The machine offers 5-axis functionality, enabling intricate and complex wood carving with high precision.

- ATC system (Automatic Tool Changer): Equipped with an ATC system, the machine allows for continuous operation by automatically changing tools based on the settings programmed in the software.

- Long-term operation: With the ATC system, the machine can work for extended periods without manual intervention, enhancing productivity and reducing downtime.

- Spacious working area: The low bed design provides ample space for carving large workpieces, accommodating the carving of sizable wood and foam materials.

- High precision carving: The 5-axis capability combined with the machine’s precise control system ensures accurate and detailed wood carving results.

- Stable and reliable operation: The heavy-duty structure and advanced driving system, such as Japan YASKAWA servo motor and driver, contribute to the machine’s stability and reliability during operation.

- Versatile material compatibility: The CNC machine is suitable for carving wood and foam, and other plastics, ACM/ACP, making it ideal for various applications, including woodworking, architectural model making, and artistic sculptures.

- Efficient tool calibration: The machine features an automatic tool sensor calibration, streamlining the tool setup process and ensuring precise carving results.

- Safety features: The machine adheres to safety standards and includes protective measures to ensure safe operation during the carving process.

- User-friendly interface: The control system, such as Syntec 610MA-E5, provides an intuitive interface for convenient operation and programming.

- Effective dust management: The machine can be equipped with a dust extraction system to minimize dust accumulation during wood carving, maintaining a cleaner work environment.

- High-speed and precise movement: With a traveling speed of 80m/min and re-positioning accuracy of ±0.03mm, the machine offers fast and accurate movement for efficient carving processes.

- Professional support: The machine is backed by professional technical support and after-sales service, providing assistance and guidance for optimal machine performance and maintenance.

Parameters

General:

| Popular model | ELECNC-1325 / 1530 / 2030 / 3050 |

| Working voltage | 380V~450V 3PH 50HZ/60HZ, According to your power |

| Table format (X,Y) | 1300*2500mm / 1500*3000mm; 2000*3000mm / 3000x5000mm; Customizable; |

| Z axis travel | 1100mm |

| Machine structure | Heavy-duty body + heat treated |

| Work table | Aluminum T-slot & vacuum work table |

| Transmission | X, Y axis: Helical Rack and Pinion |

| Z axis: High precision ball screw | |

| Traveling speed | 80m/min |

| Working speed | 0-25m/min |

| Command language | G Code / M Code |

Other details:

| Control system | Syntec 610MA-E5 |

| Tool magazine | Carousel type |

| Spindle type | DMASS spindle |

| Drilling bank | 5+4 vertical drills |

| Tool holder | Collet HSK tool holder |

| Driving moter | Servo motor |

| Reducer | Japan SHIMPO reducer |

| Positioning cylinder | 5 pieces (X2,Y3) |

| Linear guide | #35 Linear guide with dustproof |

| Lubrication system | Semi-auto |

| Tool calibration | Automatic |

| Cables | Germany brand |

Related brand / brand-location:

| Parts | Details |

| Spindle | Germany DMASS |

| Drilling bank | China Taiwan / Italy |

| Control system | Syntec |

| Driving system | Japan YASKAWA |

| Reducer | Japan SHIMPO |

| Linear guide | China Taiwan |

| Transmission | China Taiwan / Germany |

| Cables | Germany Igus |

| Tool holder | HSK |

Reviews

There are no reviews yet.