In the world of stone fabrication, precision, efficiency, and customization are paramount. To meet these demands, stone CNC machines have become indispensable tools. This article explores the common and popular stone CNC machines, such as stone CNC bridge saws, stone CNC routers, and waterjet stone cutting machines, and delves into why they are essential in modern stone fabrication.

Popular Stone Fabrication CNC Machines

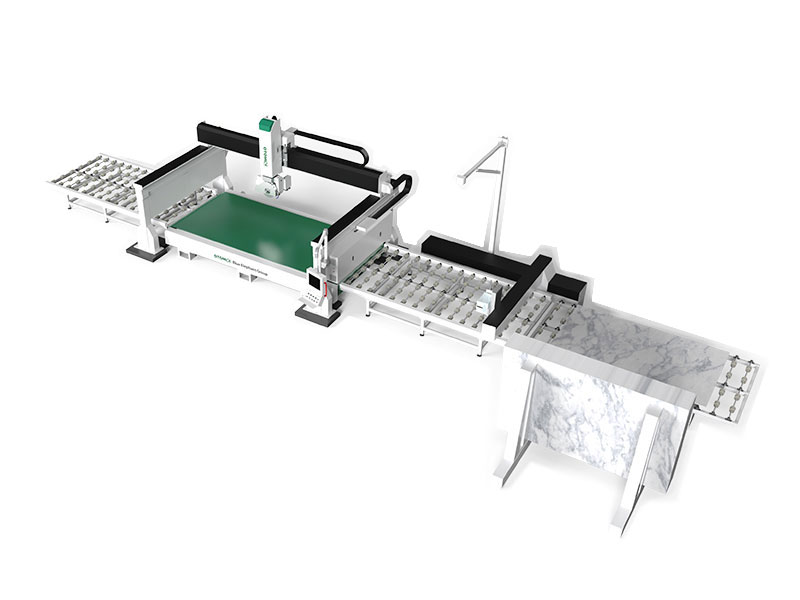

1. Stone CNC Bridge Saw

The stone CNC bridge saw is a workhorse in the stone fabrication industry. It combines the precision of a CNC system with the robust cutting power of a bridge saw. These machines are used for cutting and shaping stone slabs, making them a cornerstone of countertop, monument, and architectural stone fabrication. Stone CNC bridge saws provide clean, accurate cuts, and their computer-controlled systems ensure consistency and repeatability in complex designs.

2. Stone CNC Router

Stone CNC routers are versatile tools, equally at home with engraving intricate designs in granite as they are with carving elegant patterns in marble. These machines excel in producing detailed, 3D relief carvings and edge profiling. Stone CNC routers can be equipped with different-sized spindles and various toolsets, making them versatile for diverse stone fabrication needs. From countertops to decorative stone art, these machines play a significant role in enhancing the visual appeal of stone products.

3. Waterjet Stone Cutting Machine

Waterjet stone cutting machines utilize high-pressure water mixed with abrasive particles to cut through stone. This technology is known for its precision and ability to cut intricate patterns in various types of stone. Waterjet machines are employed for architectural elements, medallions, and inlays. They ensure minimal material waste, making them an eco-friendly choice.

The Significance of Stone CNC Machines in Modern Fabrication

In the realm of modern stone fabrication, traditional manual methods have given way to automation and precision. Stone CNC machines offer several key benefits:

Accuracy and Precision: CNC technology guarantees that every cut, carve, or engraving is exact, eliminating the potential for human error.

Efficiency: These machines work tirelessly, reducing labor hours and production time.

Customization: Modern consumers seek unique and personalized stone products, which can be achieved efficiently through CNC machines.

Complex Designs: Stone CNC machines can create intricate, complex patterns and shapes that would be impractical or impossible with traditional tools.

In conclusion, stone CNC machines have revolutionized the stone fabrication industry. They provide the means to meet the demands for precision, efficiency, and customization in modern stone products. From stunning countertops to intricate sculptures, these machines are the backbone of the stone fabrication world.